In the context of vigorously developing intelligent manufacturing, the new generation of information technology with AI as the core is accelerating its integration in the industrial field. Machine vision is one of the typical applications of AI technology in industry.

Machine vision is a comprehensive technology. A typical machine vision software system includes image capture, light source system, image digitization module, digital image processing module, intelligent decision-making module, and mechanical control execution module. In the field of machine vision, a dedicated controller using deep learning and computer vision technology can quickly identify and locate target features in captured images, accurately recognizing objects, vehicles, faces, etc. In the manufacturing industry, machine vision software, supported by dedicated controllers, can realize image acquisition, quality control, automated production, and other functions, thereby improving production efficiency, reducing costs, and minimizing human errors. Additionally, dedicated machine vision controllers are widely used in target detection and recognition, image inspection, positioning measurement, product sorting, and play an important role in predictive maintenance.

JHCTECH adheres to the strategic goal of “Scenarios empowering product innovation” and has been committed to providing product solutions that meet scenario needs for users in various industries. The machine vision dedicated controller KMDA-5611/6611 have been developed in response to this.

Let’s follow our steps to see the impressive features of these two star products!

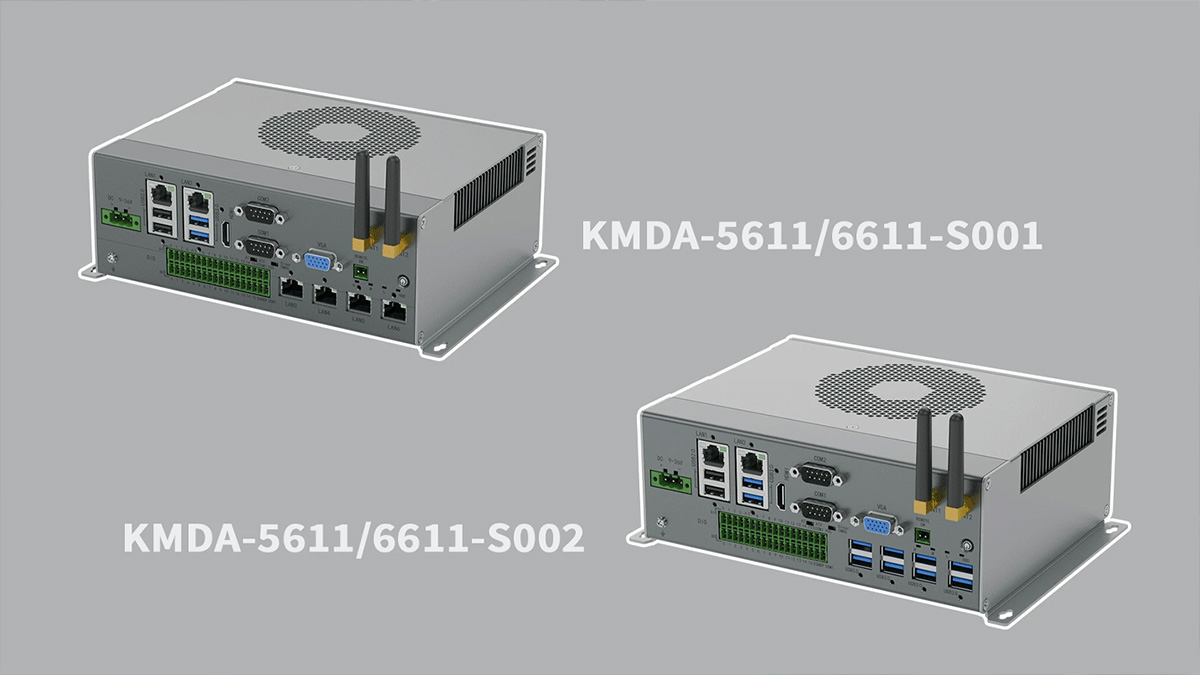

KMDA-5611/6611 are high-performance box PC. The KMDA-5611 adopts the H310 chipset, equipped with Intel® 8th/9th generation Coffee Lake series processors; the KMDA-6611 uses the H420E chipset, equipped with Intel® 10th generation Comet Lake series processors. They offer rich I/O functions, and their moderate size makes them suitable for industries and fields such as machine vision and industrial control.

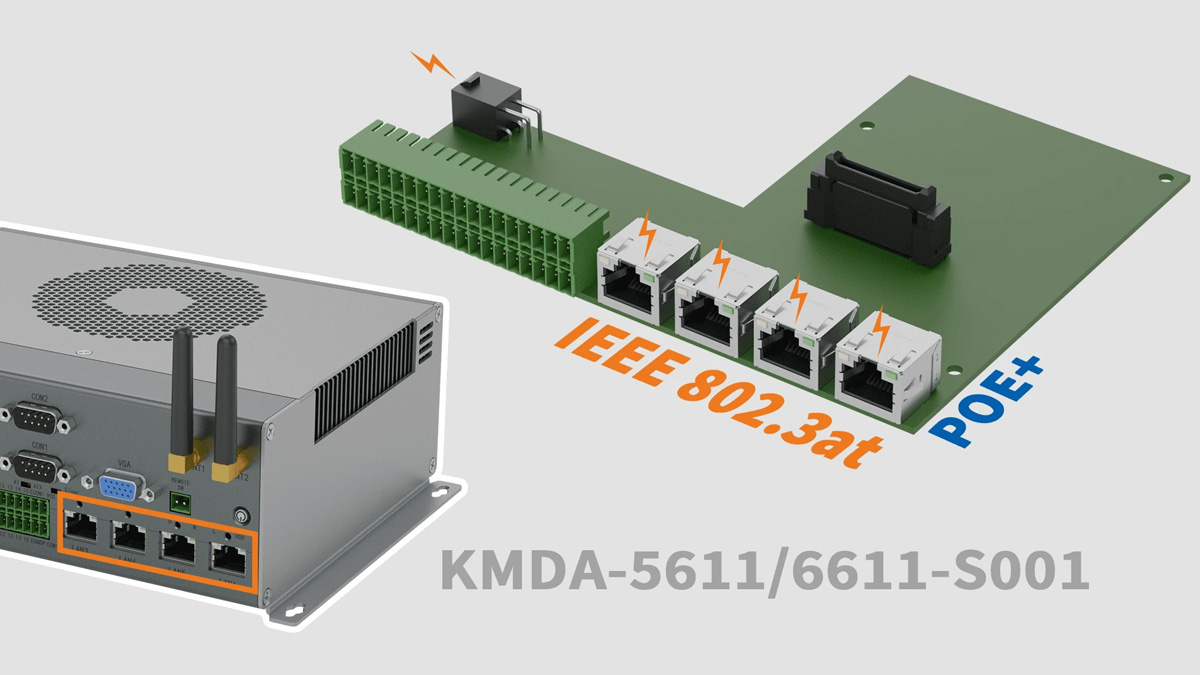

Multi-port POE+ network port design

- Simultaneous transmission of data and power, reducing the number of system cables and lowering wiring costs

- Supports connection of more vision components (high-definition industrial cameras, smart cameras, encoders, light source controllers, etc.)

- Compliant with IEEE 802.3at standard, supports advanced management functions such as remote device power control, energy consumption monitoring, fault isolation, and improving system intelligence management.

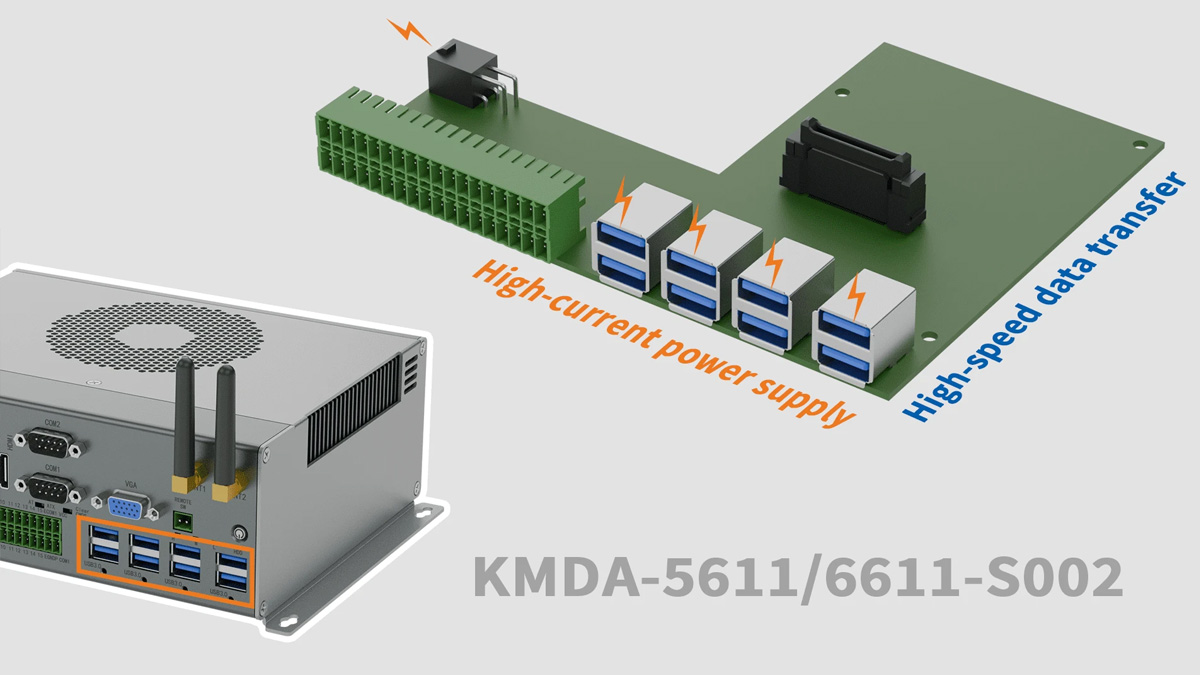

High-current power supply for USB3.0

- 8-channel high-current power supply USB3.0 interface can provide sufficient power support to more high-power devices (such as high-performance industrial cameras, sensors, LED lighting, etc.), especially suitable for machine vision applications requiring high-brightness illumination or high-speed image capture.

- Achieve fast data transmission to meet the processing requirements of large amounts of data in the field of machine vision, plug and play, convenient for device connection and replacement.

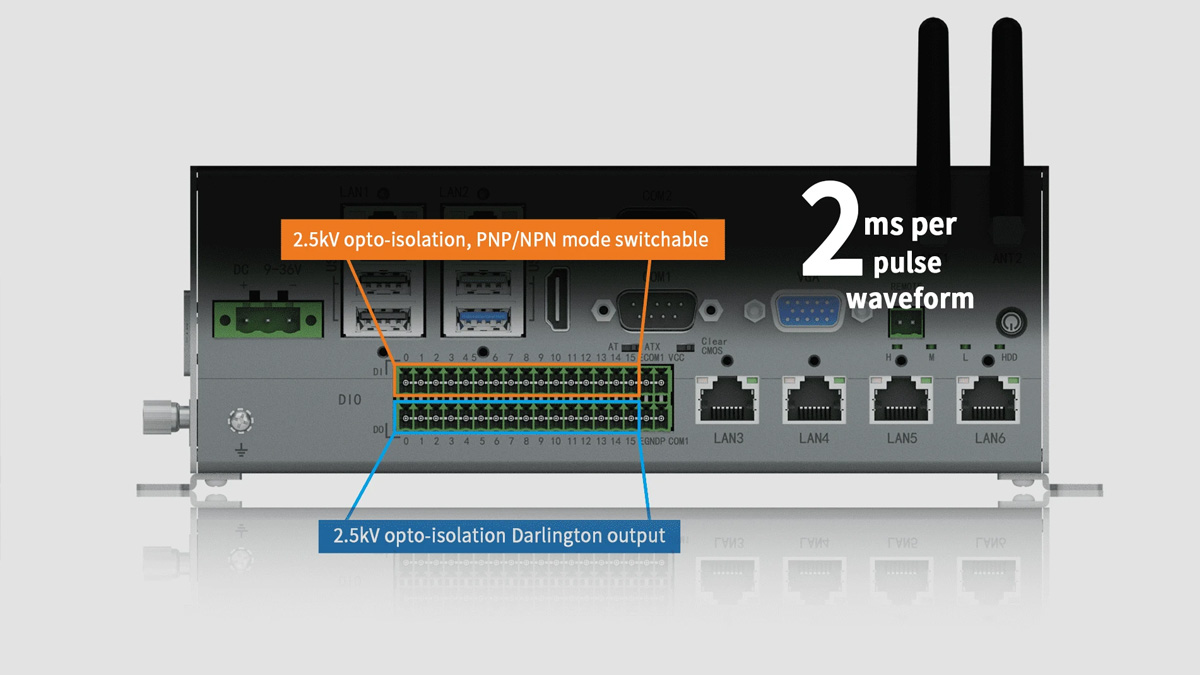

32-channel high-speed isolated DIO

- 32-bit Isolated DIO, 16-bit DI with 2.5KV Optical Isolation, supports switchable PNP and NPN modes; 16-bit DO with 2.5KV optically isolated Darlington output, built-in matching resistors, selectable according to different drive currents

- Effectively prevents ground loops, noise interference, voltage surges, etc., enhancing the overall anti-interference capability of the system and the reliability of data transmission

- Pulse cycle reaches 2ms/pulse wave, enabling fast response and precise control of various digital devices such as triggers, relays, motor drivers, and accurately collecting digital signals from sensors, encoders, and other equipment.

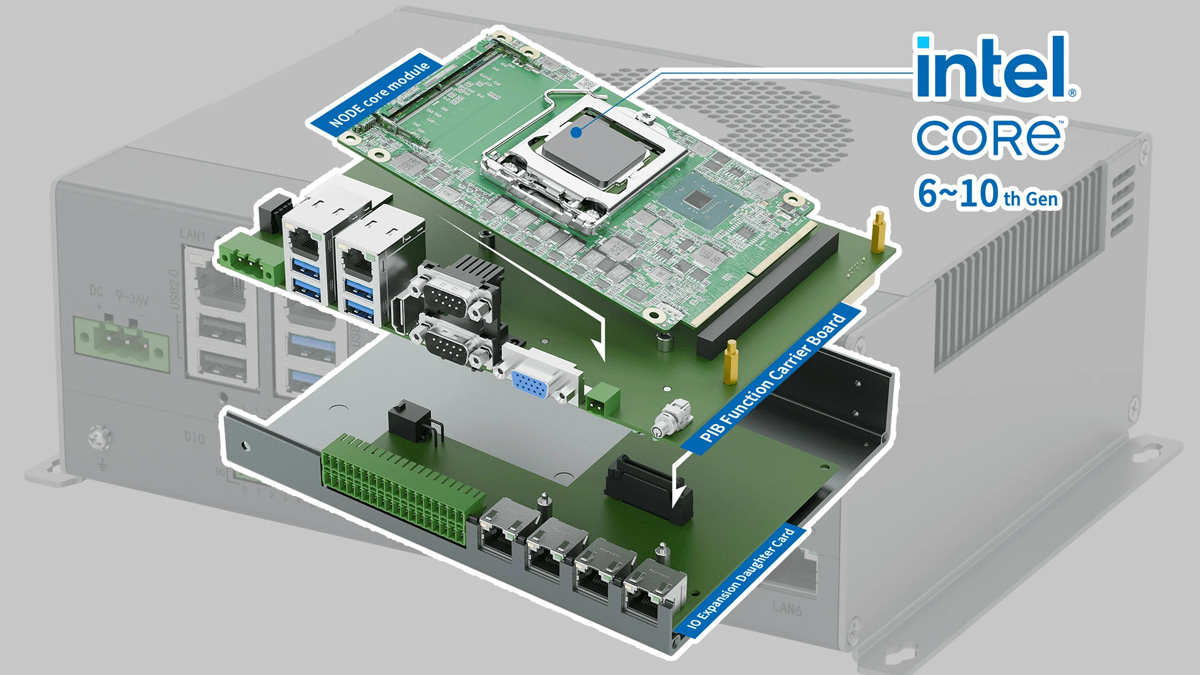

Modular design with easy CPU upgrades

NODE core module + PIB function carrier board + IO expansion daughter card combination design, allowing easy CPU upgrades from 6th to 10th generation

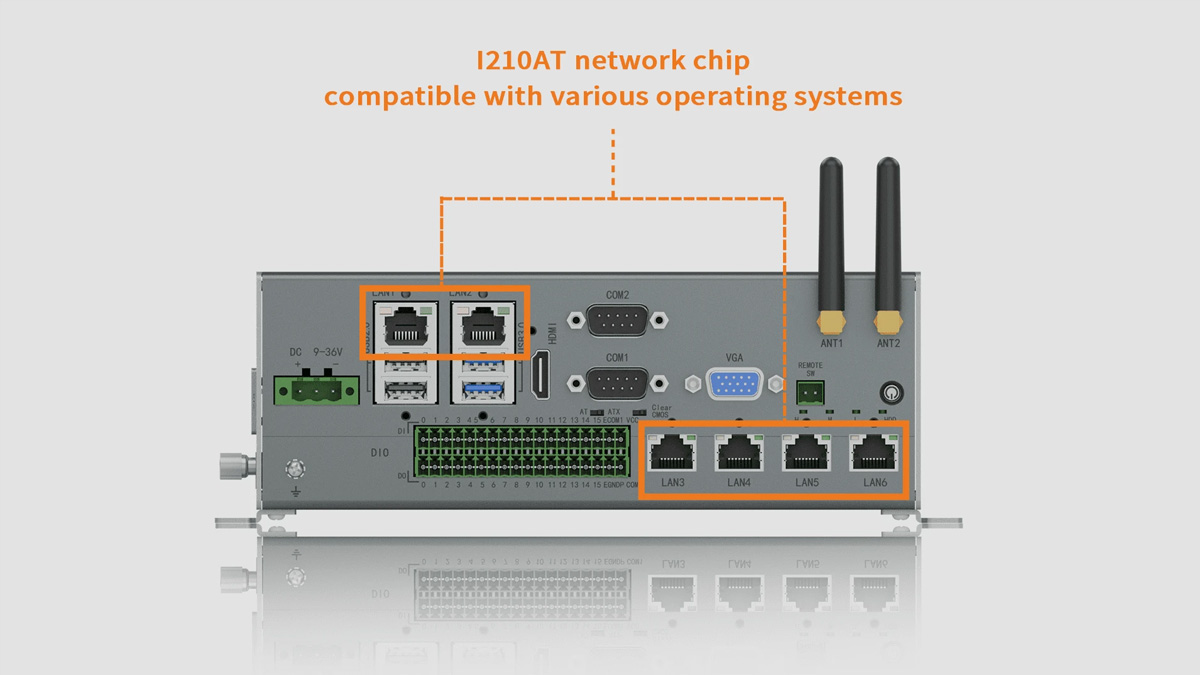

I210AT network chip, compatible with various operating systems

I210AT network chip, high stability and versatility, compatible with various operating systems

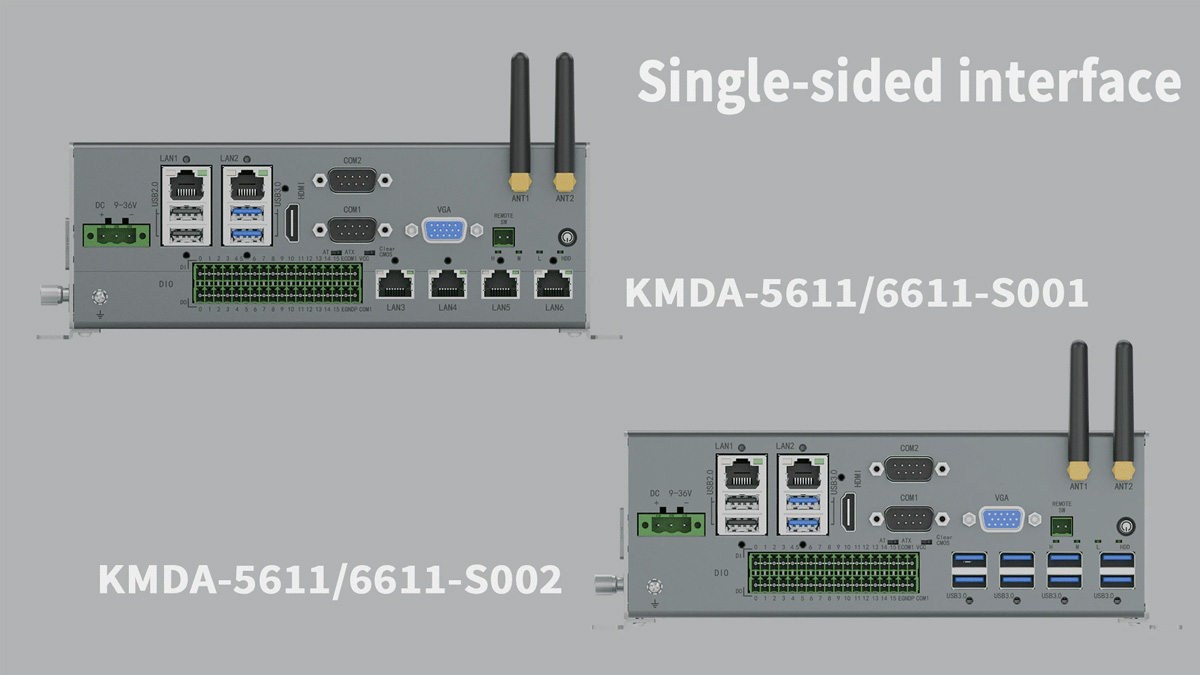

Single-sided interface, simplified application wiring

- Makes cable connections, equipment installation, and subsequent maintenance more intuitive and straightforward

- Helps reduce equipment depth, especially suitable for space-constrained industrial environments such as compact control cabinets, embedded workstations, or wall-mounted installation scenarios. This can optimize internal chassis space utilization, providing more room for arranging other critical components.

Diverse installation options

Market Directions

Machine Vision

- Logistics Vision

- Sorting photovoltaic Vision Inspection

- Intelligent Qauality Inspection Machines

- Automotive Manufacturing Inspection

Productionindustri

- Industrial Robotic Arms

- Laser Cutting Machines/Engraving – Machines/CNC Machining Centers

- Dispensing Machines/3D Printers Distributed control systems

- Distributed control system (DCS)

This news was first published on the JHCTECH website

Other JHCTECH products

Find more JMC TECH products on the Nord Technology product site

More on JHCTECH

JHC Technology has been producing robust industrial hardware for more than 20 years.

Contact us and book a meeting:

Kevin Peter Gade

As always, our door, telephone or mail box is open, should the above give rise to questions or simply for a chat and sparring.

Send a Email

Or contact us by phone at +45 7027 0415

Sign up for our newsletter to be updated about the new products and solutions we offer.