New Edge Controller for industrial needs

New Edge Controller for industrial needs

– developed based on feedback from the market

At Nord Technology, we recognize the importance of tackling unique industrial

challenges where standard solutions are not sufficient. Our collaboration with our suppliers, including TAICENN Industrial Computing, enables us to deliver customized solutions that precisely meet the unique needs of various industries and directly address market demands.

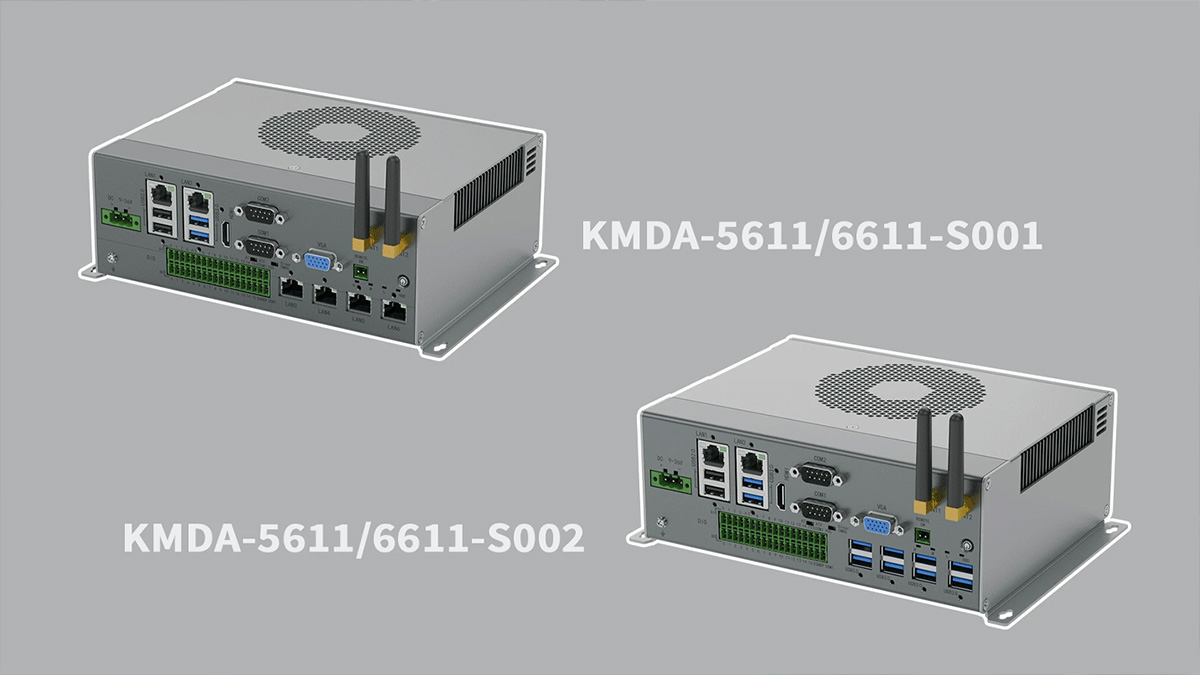

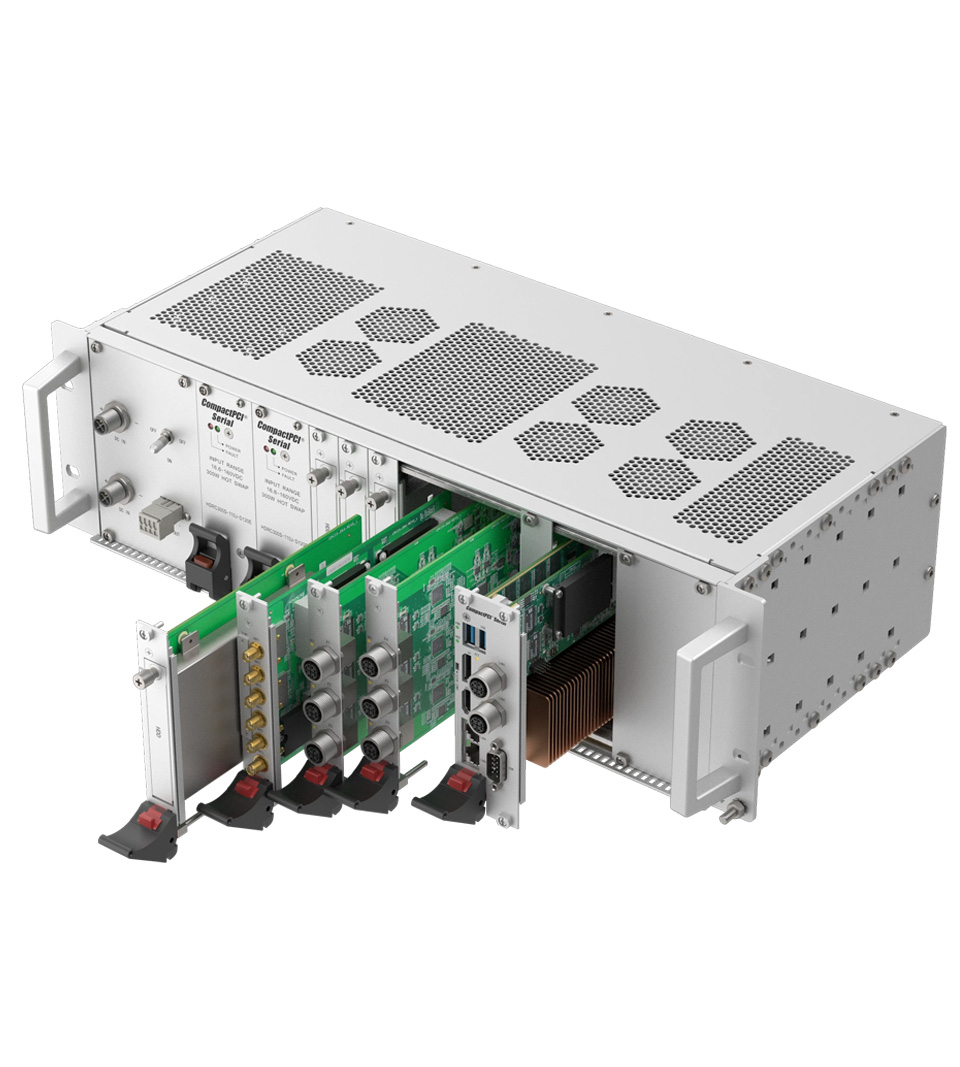

Introducing the TBOX-6xx5 Series

The TBOX-6xx5 series is the latest addition to our product line of compact and powerful Edge

controllers, designed to operate under demanding conditions. This series offers a wide range of CPU and I/O configurations, making them ideal for many different industrial applications, including manufacturing systems and industrial IoT solutions.

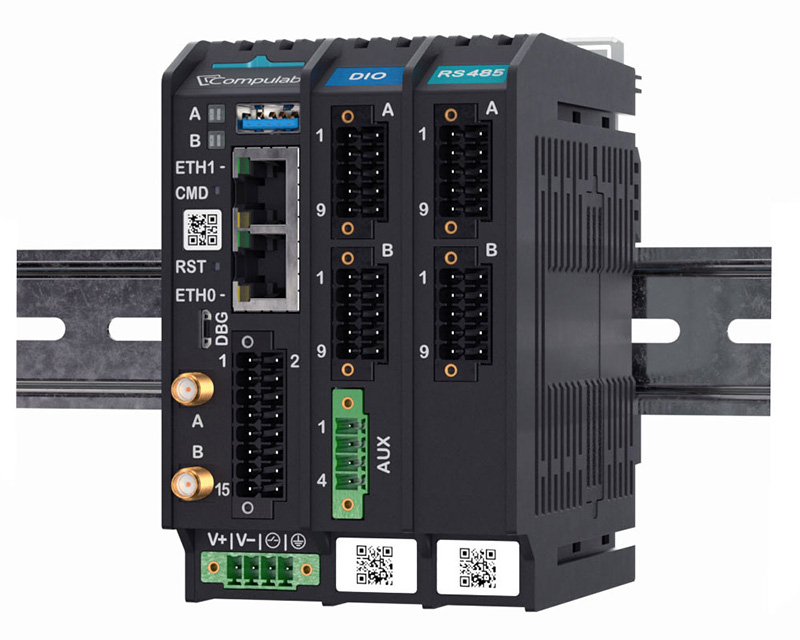

Spotlight on TBOX-6D25

One of the products in this series is the TBOX-6D25 model. This Edge Controller is equipped with an Intel Core i5 CPU and delivers high performance, despite its small size and fanless design. The material is anodized aluminium, which provides optimal heat conduction and release, and the construction is robust and can withstand an ambient temperature of -20 ~ +60. 12/24V power input, TPM 2.0 and optimal °C form factor for mounting on a DIN rail for example board mounting. This is among the most requested requirements from the market and TBOX-6 has been developed with this in mind.

Specifications

TBOX-6D25

- Rugged & Slim design, fanless design;

- Intel 12th Gen. Alder Lake-U Core i5-1235U 2P/8E core processor;

- Single DDR4 memory, up to 32GB, 1* M.2 2280 NVMe storage;

- DC terminal 12/24V input, auto detect;

- 2 GbE, optional with Wi-Fi/BT wireless function;

- 6 USB3.0, 1 HDMI, 1 DP, Audio;

- 2 M.2 fast-speed expansion slots;

- DIN-rail mount

- Industrial operating temperature range -20 ~ +60 °

Flexibility and security

The TBOX-6D25 supports TPM2.0 and is compatible with Windows 10 IoT, Windows 11 IoT and newer Linux distributions, making it a versatile solution for a wide range of industrial applications. We offer them both with and without control voice and central management solution.

More information about the TBOX-6D25 and TBOX-6xx5 series

For more information and direct ordering of the TBOX-6D25 sample or other models in the TBOX-6xx5 series, visit our product site

Contact us and book a meeting:

Kevin Peter Gade

As always, our door, telephone or mail box is open, should the above give rise to questions or simply for a chat and sparring.

Send a Email

Or contact us by phone at +45 7027 0415

Sign up for our newsletter to be updated about the new products and solutions we offer.